Static Earthing Verification – Newson Gale

If static electricity can build up on process equipment, the energy content of a static discharge can be the cause of fire and/or explosions in ATEX environments.

Static grounding of process equipment and other objects prevents the build-up of electrostatic charges, and thus also prevents the potential danger.

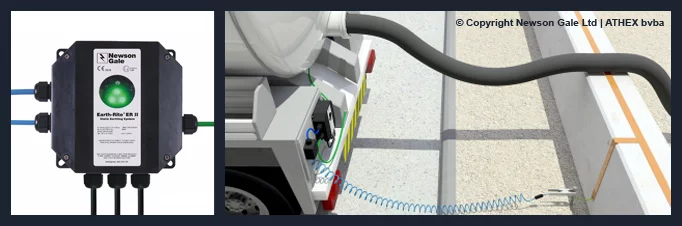

Newson Gale ground control systems continuously monitor if static grounding loops have low enough resistance to eliminate static electricity, report this to the user, and possibly stop processes in case of a faulty earthing, so that no further build-up of static charge can take place.

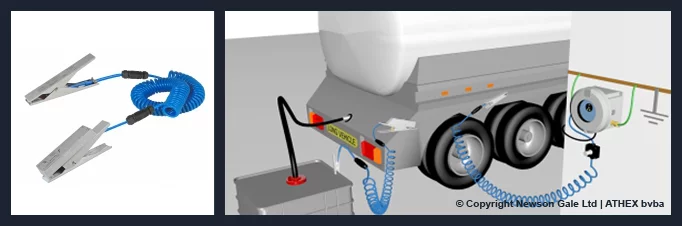

Tanker & bulk trucks

8 channel grounding system

Overview static grounding systems

Ground control systems are able to detect faulty connections between object an earth. In this situation a safe static discharge can’t be guaranteed, and the process must be stopped using an Earth-Rite grounding system to avoid further building up of static charge on the object.

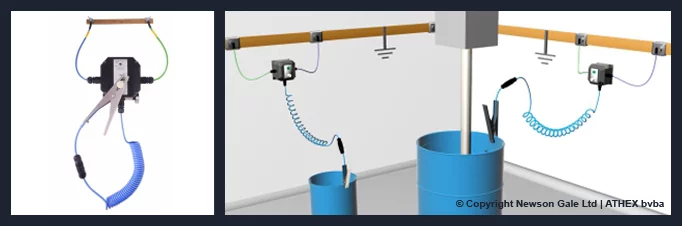

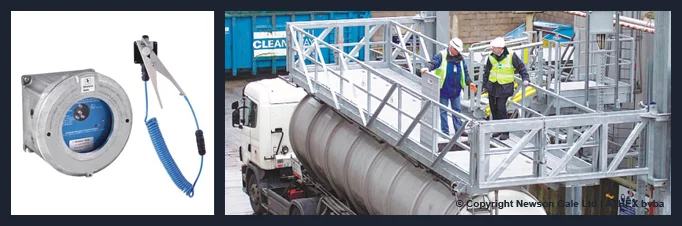

Earth-Rite® RTR

Tankertrucks and bulk trucks

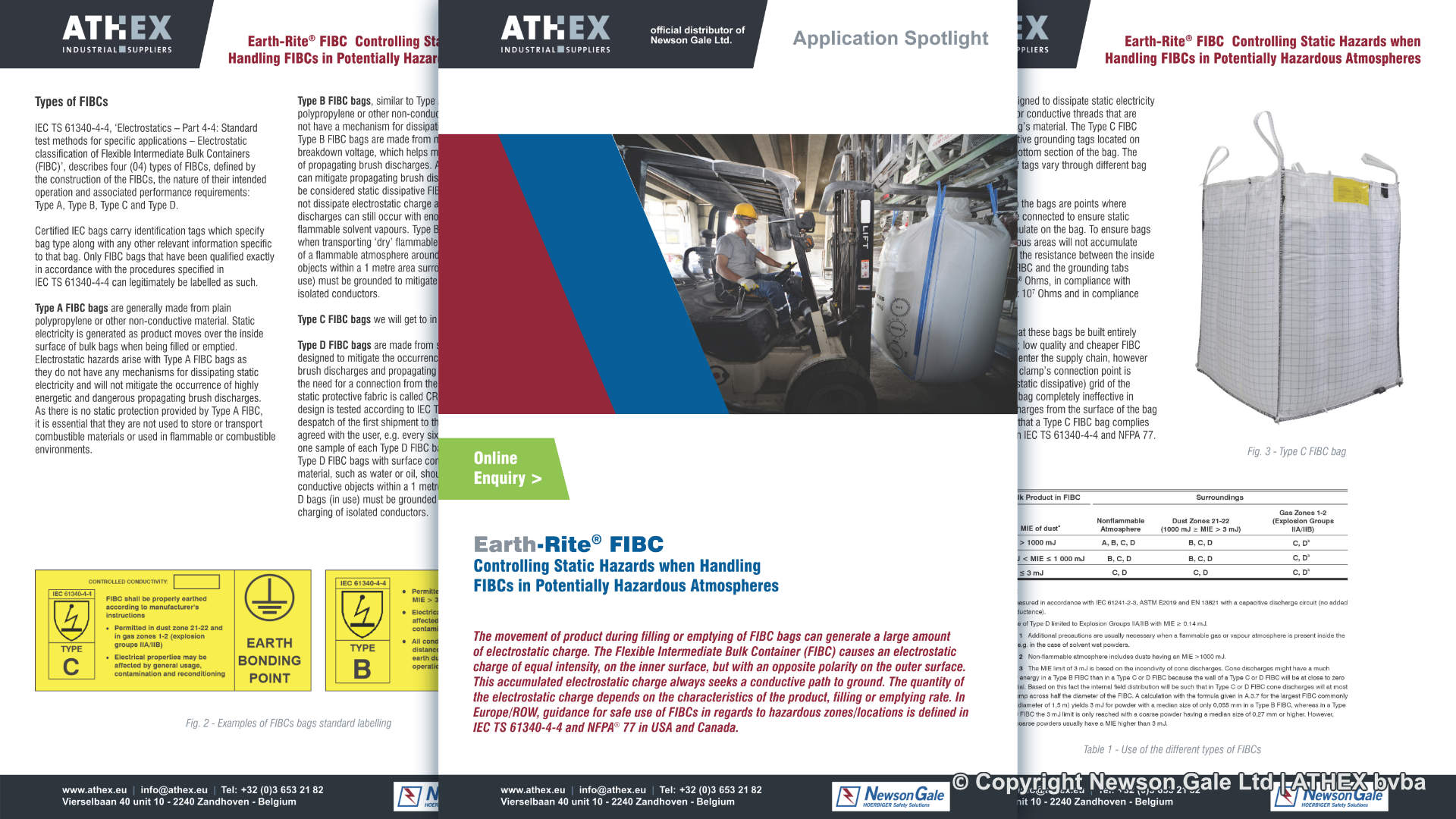

Earth-Rite® FIBC

Conductive liners and plastics, FIBCs type C

Earth-Rite® PLUS

Vessels, containers, IBC’s, railcars,…

Earth-Rite® DGS

Dual Grounding System

Earth-Rite® OMEGA

DIN-rail module for OEM

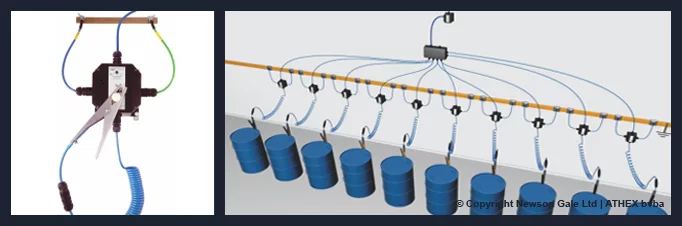

Earth-Rite®MULTIPOINT

Multi-channel grounding systems for processes

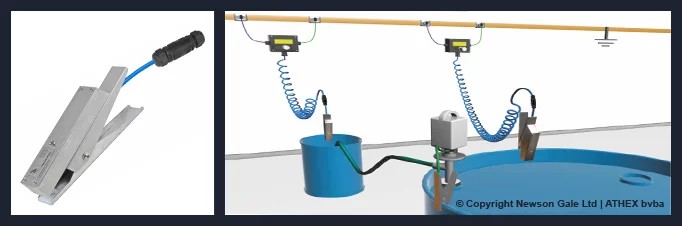

If it’s undesirable, or there is no possibility to interrupt processes, the Bond-Rite grounding devices offer an ideal solution. These earthing control systems check whether a safe disposal of static electricity can be guaranteed by detecting faulty connections between object and verified earth. If this is not the case, the user will be alerted.

Self Monitoring Grounding Clamp

Self Monitoring Grounding Clamp