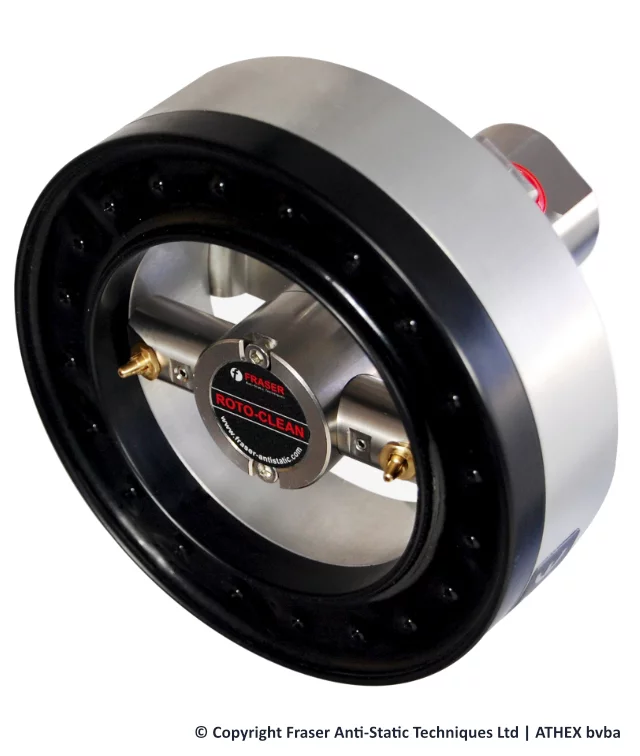

4900 Roto-Clean

Revolutionary ionising solution for very accurate and optimal cleaning of complex objects

Description

- Removes charge, cleans and prevents re-attraction of dust

- Better cleaning with lower compressed air cost

- Higher quality output with less rework

A Revolution in Anti-Static Cleaning

Roto-Clean revolutionises the cleaning of mouldings and components where careful control of contaminants is necessary to reduce the cost of rework and rejects. Roto-Clean combines an advanced ioniser with the power of high-thrust, rotating air jets to enable accurate and powerful cleaning of all shapes and sizes of product.

Applicable markets

Roto-Clean is suitable for cleaning mouldings and components of all shapes and sizes in the automotive, medical, pharmaceutical and technical moulding industries.

Maximising efficiency and results

- Pulsing high-speed air cleans more quickly and accurately preventing rework>

- Multi-directional ionised airflows clean the most complex shapes and crevices>

- Ionised air neutralises static charge and prevents reattraction of dust>

- Reduced air consumption lowers running cost while maximising efficiency

- Better cleaning effect that airknives or fixed nozzles

- Simple to retrofit to conveyors, cleaning stations or attach to robot arms

- Flexible in use, capable of scaling for the largest products

How Roto-Clean works

Roto-Clean consists of a dual-nozzle rotary bar driven by a patented centrifugal control integrated into a circular static-eliminator. The unique static-eliminator provides 360° ionisation of the air coming from the nozzles – for maximum static neutralisation.

The nozzles require no additional power source and rotate at 60rps to produce a pulsed airflow that hits the product up to 240 times per second, blasting away contamination from various angles to clean crevices.

This gives better cleaning than conventional nozzles and airknives, with lower air consumption.